-40%

KIT of 33' gasFlex+fittings 1/2" tubing pipe FIRE PIT, Space Heater, BBQ

$ 25.87

- Description

- Size Guide

Description

BRAND NEW 33´ (10m) ROLL with TWO (2) 1/2" NPT MALE fittingsPreassembled

, one on each end - Ready to install

This is all you need to install that extra gas line to the new

Barbecue

or Fireplace or Space heater

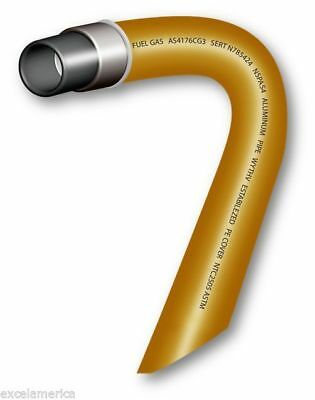

FLEXIBLE ALUMINUM PIPE WITH INSIDE AND OUTSIDE PE COVER

1/2"

1216 Size

Yellow Color

You are bidding on the world famous gasFlex flexible gas piping.

Used in Europe and Australia for over 10 years, this technology is now revolutionizing the way we pipe gas in America.

gasFlex

is a multi-layered composite tubing consisting of an interior aluminum tubing lined with inner and outer layers of UV resistant polyethylene (PE). It is a durable, reliable tubing that will not corrode or rust. The flexibility of gasFlex tubing results in easy rollouts. The stay-in-place rigid feature of the tubing makes it ideal for:

Adding interior gas piping runs

Underground gas piping systems

Running gas lines to remote areas in the yard

(Fire PIT ,BBQ -Jacuzzi - Space heater)

gaslite systems

ALUMINUM TUBING IS LISTED IN

NFPA54

FOR GAS USE

If you want to know a little more about

gasFlex

:

The PE layers protect against corrosion and creates a shield so the tubing can be embedded in concrete.

The aluminum layer provides stiffness to hold the tubing in the desired shape and fire resistance.

Together, the layers make up a flexible tubing that stays in place, won't discolor and has a very low thermal expansion rate (similar to copper and steel).

SUMMARY of ADVANTAGES

The inner and outer layers of composite multilayer

gasFlex

are UV treated Poliethylene; and its middle layer is a flexible aluminum tube.

gasFlex

has most of the advantages metallic pipe. Its advantages are easy bending, anti-rust, non-corrosion, and fire resistance.

gasFlex 's

inner and outer layers consist of PE with U.V resistant components. At normal temperature, it does not dissolve in any known solutions and is resistant against acid, alkaline or salty soil.

Both materials offer perhaps the best chemical and corrosion resistance of any plastic used in the manufacture of plumbing pipes. The polyolefin family of plastics PE is renowned for it's toughness, long working life and resistance to deterioration in the most extreme environments.

On the other hand, when metal or copper pipes are exposed to aggressive soil and conditions, they are susceptible to corrosion and pitting.

Ease of Installation

No more copper sticks, no more sweating joints every few feet.

gasFlex

's

convenient, lightweight coils allow you to install a professional gas piping system quickly and efficiently. Installation crews are less fatigued and larger coils mean less wastage.

Need to make a bend ? Go ahead. Need to snake pipe around an obstruction ? There's nothing stopping you. When the system calls for a fitting, you simply cut, bevel, insert and crimp the pipe for secure, long-term connections. It's really that fast and simple.

Go anywhere with gasFlex

gasFlex

can be installed behind drywall and above false ceilings or surface mounted. It can be supported horizontally or vertically on 8 foot centers because its stiffness and expansion rate is similar to copper's. gasFlex

can be encased in concrete or buried underground without additional protection because its tough outer plastic layer resists chemicals and corrosive activity.

Superior Flow

gasFlex's

smooth inner wall toughened with carbon black permanently resists scaling and abrasion, keeping gas flow constant year after year.

gasFlex

uses fewer fittings, in fact less than half the fittings used in a copper or black iron system. Fewer fitting joints means less chance of leakage and less liability.

PRESSURE DROP TABLES:

NATURAL GAS

gasFlex 1/2" 1216

PRESSURE LOSS in "W.C. per foot -

NATURAL GAS

0.64 Specific Gravity

Flow

POWER

PRESSURE LOSS

cfh

BTUH

"W.C./ foot

26

27,283

0.024

39

40,925

0.048

52

54,567

0.070

62

64,798

0.137

75

78,439

0.192

78

81,849

0.206

81

85,260

0.222

99

103,704

0.314

107

112,543

0.360

113

118,518

0.399

120

125,852

0.444

130

136,404

0.512

134

140,741

0.543

141

148,148

0.596

150

157,333

0.665

159

166,667

0.738

168

175,926

0.814

177

185,185

0.894

194

203,704

1.065

212

222,222

1.250

230

240,741

1.449

247

259,259

1.662

265

277,778

1.889

282

296,296

2.130

300

314,815

2.385

318

333,333

2.654

335

351,852

2.937

353

370,370

3.234

LPG GAS (PROPANE)

gasFlex 1/2" 1216

PRESSURE LOSS in "W.C. per foot -

LPG PROPANE GAS

1.55 Specific Gravity

Flow

POWER

PRESSURE LOSS

cfh

BTUH

"W.C./ foot

8

20,000

0.002

16

40,000

0.007

20

50,000

0.010

26

65,600

0.017

39

98,400

0.034

52

131,200

0.058

62

155,800

0.080

75

188,600

0.114

78

196,799

0.123

81

205,000

0.132

99

249,345

0.192

107

270,599

0.222

113

284,966

0.246

120

302,598

0.276

130

327,971

0.321

134

338,397

0.340

141

356,207

0.374

150

378,292

0.421

159

400,733

0.471

168

422,996

0.523

177

445,259

0.578

194

489,785

0.690

212

534,311

0.818

230

578,837

0.958

247

623,363

1.099

265

667,889

1.260

282

712,415

1.421

300

756,940

1.603

318

801,466

1.795

335

845,992

1.987

353

890,518

2.201